The integration of automation and data exchange in manufacturing technologies is commonly referred to as Industry 4.0, the forth industrial revolution.

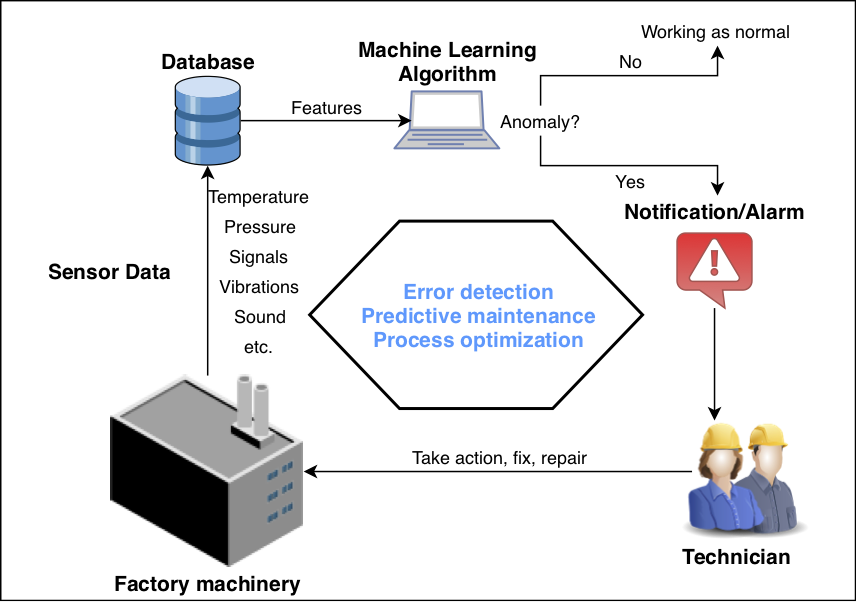

One application case in this industrial revolution is the automated fault detection, or anomaly detection, in industrial processes. Anomalies are by definition rare events, that are deviating from the standard or normal behavior. Due to the amount of time-series data created by industrial machinery, the diversity of processes and the rarity of anomalous events, system that detect anomalies with a threshold based system require an enormous work and time effort to be set up or are prone to miss the desired events. Therefore, a new approach as to be explored.

In this thesis, we would like to explore the possibilities of machine learning techniques to detect anomalies in time-series data, that might facilitate the installation of autonomous anomaly detection system, handle the complex interactions of different measurements and the rarity of anomalies by learning the state of normal behavior.

Publications

-

![[PDF]](https://icosys.ch/wp-content/plugins/papercite/img/pdf.png) L. Rychener and J. Hennebert, “Machine Learning for Anomaly Detection in Time-Series Produced by Industrial Processes,” in FTAL conference on Industrial Applied Data Science, 2018, p. 15–16.

L. Rychener and J. Hennebert, “Machine Learning for Anomaly Detection in Time-Series Produced by Industrial Processes,” in FTAL conference on Industrial Applied Data Science, 2018, p. 15–16.

[Bibtex]@InProceedings{ftalconference2018lorenz, author = {Lorenz Rychener and Jean Hennebert}, title = {Machine Learning for Anomaly Detection in Time-Series Produced by Industrial Processes}, booktitle = {FTAL conference on Industrial Applied Data Science}, pages = {15--16}, year = {2018}, month = {oct}, isbn = {978-2-8399-2549-5}, }

-

![[PDF]](https://icosys.ch/wp-content/plugins/papercite/img/pdf.png)

![[DOI]](https://icosys.ch/wp-content/plugins/papercite/img/external.png) L. Rychener, F. Montet, and J. Hennebert, “Architecture Proposal for Machine Learning Based Industrial Process Monitoring,” Procedia Computer Science, vol. 170, p. 648–655, 2020.

L. Rychener, F. Montet, and J. Hennebert, “Architecture Proposal for Machine Learning Based Industrial Process Monitoring,” Procedia Computer Science, vol. 170, p. 648–655, 2020.

[Bibtex]@article{rychener2020architecture, title={Architecture Proposal for Machine Learning Based Industrial Process Monitoring}, author={Rychener, Lorenz and Montet, Fr{\'e}d{\'e}ric and Hennebert, Jean}, journal={Procedia Computer Science}, volume={170}, pages={648--655}, year={2020}, publisher={Elsevier}, issn = {1877-0509}, doi = {https://doi.org/10.1016/j.procs.2020.03.137}, url = {http://www.sciencedirect.com/science/article/pii/S1877050920305925}, keywords = {System Architecture, Rule Engine, Anomaly Detection, Monitoring, Industry 4.0}, abstract = {In the context of Industry 4.0, an emerging trend is to increase the reliability of industrial process by using machine learning (ML) to detect anomalies of production machines. The main advantages of ML are in the ability to (1) capture non-linear phenomena, (2) adapt to many different processes without human intervention and (3) learn incrementally and improve over time. In this paper, we take the perspective of IT system architects and analyse the implications of the inclusion of ML components into a traditional anomaly detection systems. Through a prototype that we deployed for chemical reactors, our findings are that such ML components are impacting drastically the architecture of classical alarm systems. First, there is a need for long-term storage of the data that are used to train the models. Second, the training and usage of ML models can be CPU intensive and may request using specific resources. Third, there is no single algorithm that can detect machine errors. Fourth, human crafted alarm rules can now also include a learning process to improve these rules, for example by using active learning with a human-in-the-loop approach. These reasons are the motivations behind a microservice-based architecture for an alarm system in industrial machinery.} }